Resources

How to improve the quality of mold parts?

Release time:2023-09-13

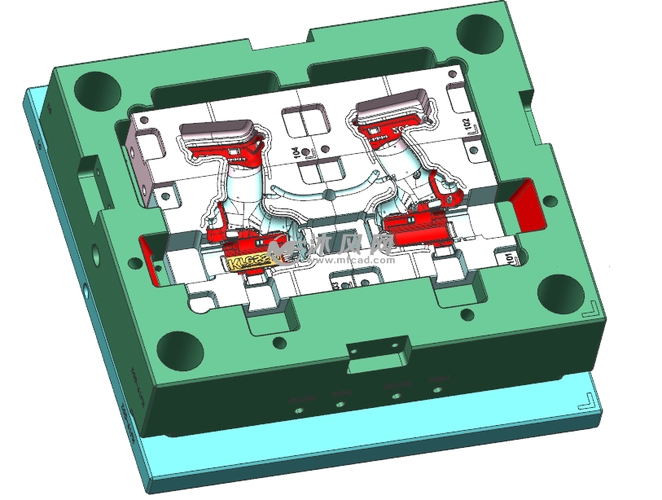

How to improve the quality of mold parts?

As we all know, mold accessories as a combination of mold parts, the quality of its good or bad to a certain extent, directly affect the quality and service life of the mold. Therefore, in order to better use the mold, improve the quality of mold parts is a very necessary thing. So do you know how to improve the quality of mold parts? The following Ideal for your introduction:

Methods to improve the quality of mold parts:

① mold parts design should be reasonable, as far as possible to choose a good structural program, the designer of the parts to take into account the technical requirements of the parts and their structure must be consistent with the mold manufacturing process and feasibility.

② the main forming parts of the mold surface strengthening, in order to improve the mold parts surface wear resistance, so as to better improve the quality of mold parts. For surface strengthening, according to different uses of the mold, choose different strengthening methods.

③ the mold design is to improve the quality of mold parts an important step, need to take into account a lot of factors, including the selection of mold materials, mold structure can be used and safety, mold parts can be processed and the convenience of mold maintenance, these in the beginning of the design should try to take into account a more thorough.

④ the mold manufacturing process is to ensure the quality of mold parts is also an important part of the mold manufacturing process of processing methods and processing accuracy will also affect the service life of the mold. The accuracy of the parts directly affects the overall assembly of the mold, in addition to the impact of the precision of the equipment itself, it is necessary to improve the processing of parts through the improvement of the processing methods, improve the technical level of the clampers in the mold grinding process to improve the precision of the mold parts; if the overall assembly of the mold is not up to the requirements, it will be in the mold in the test to let the mold in the abnormal state of the action of the chances of increasing the overall quality of the mold will have a Great impact on the overall quality of the mold.

⑤ the correct use of the mold and maintenance, but also to improve the quality of mold parts of a major factor. In the correct use of the mold, but also need to carry out regular maintenance of the mold, mold guide pillar, guide bushings and other relative movement of the parts should be frequently refilled with lubricant, for forging die, plastic mold, die casting molds and other molds in each mold forming before the lubricant or molding agent should be sprayed on the surface of the formed parts. Planned protective maintenance of the mold, and through the maintenance process of data processing, can prevent the mold in the production of problems that may arise, but also to improve the efficiency of maintenance work.

To sum up, it is the way to improve the quality of mold parts. We want to improve the quality of mold fittings, must be considered in every aspect of the impact on the quality of mold fittings, and secondly through the full cooperation of all departments, only in this way, can more effectively improve the quality of mold fittings.

If you have any project requirements, please contact us for a quote, thank you for watching!

Posts by Topic

Recent Posts

- What affects injection mold machining accuracy and productivity?

- Shenzhen top five mold manufacturers: how plastic products are processed and produced?

- Shenzhen Ideal Vowin mold manufacturer: how to effectively improve the precision of mold processing?

- Chrome plating, a process that makes cars stylish

- Six injection molding processing technologies for home appliance plastic products

- Advantages and disadvantages of injection molding vs blow molding

- What is automotive hot stamping and molding technology?

- What is the difference between a hot runner and a cold runner in the mold?

- Automotive stamping die in large, precision and other areas of progress is obvious, the rapid development of plastic and rubber molds

- The top ten problems that are likely to occur in the mold testing process