Resources

Why does mold wear and tear occur

Release time:2023-09-09

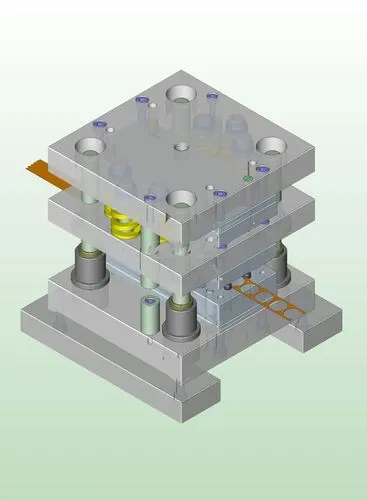

Mold wear and tear reasons

1:the main working parts of the mold material problems, improper material selection. Poor material properties, not wear-resistant; mold steel unrefined, with a large number of smelting defects; convex-concave mold, forging billet reforging process is not perfect, the legacy of heat treatment hidden problems.

2:mold structure design problems, punch die structure is unreasonable. Elongated convex mold is not designed to strengthen the device, the outlet is not smooth to appear stacked, the unloading force is too large for the convex mold to withstand the alternating load intensification, and so on.

3:the mold making process is not perfect, mainly in the convex, concave die forging blanks of poor intrinsic quality, heat treatment technology and process problems, resulting in convex, concave die quenching impermeable, there are soft spots and uneven hardness. Sometimes produce micro-cracks, or even cracks, grinding and polishing is not in place, the surface roughness value is too large.

4:No lubrication or lubrication but the effect is not good.

Any questions please contact us

Posts by Topic

Recent Posts

- What do we need to pay attention to the plastic mold machining process and machining procedures?

- What kinds of plastic mold materials?

- What is the process of mold manufacturing?

- What should be paid attention to the polishing of injection molds?

- What is easy to ignore when maintaining and overhauling injection molds?

- What are the 6 systems of plastic molds?

- What are the methods of strengthening the surface of injection molds?

- What are the methods of insulation for injection molds?

- How to solve the problem of injection mold release difficulty?

- How can we increase the brightness of ABS injection molded parts?