Resources

How can we increase the brightness of ABS injection molded parts?

Release time:2024-04-03

How can we increase the brightness of ABS injection molded parts?

ABS injection molded parts how to increase the brightness? Ideal Vowin plastic mold manufacturer editors to make a detailed explanation of this issue:

First, the injection mold

1. If the mold cavity processing is poor, such as scars, microporous, abrasion, roughness and other deficiencies, will inevitably react to the injection molded parts, so that the injection molded parts poor gloss, in this regard, we must carefully process the mold, so that the surface of the cavity to keep the roughness low, if necessary, can be polished chrome plating.

2. If the cavity surface has oil, water, or mold release agent is used too much, will make the surface of the injection molded parts dark, no luster, in this regard, to remove oil and water in a timely manner, and limited use of mold release agent.

3. If the injection molding parts demolding slope is too small, demolding difficulties, or demolding force is too large, will lead to the injection molded parts surface luster is not good, in this regard, to increase the demolding slope.

4. If the mold exhaust is poor, too much gas stays in the model, it will also lead to poor luster, in this case, check and correct the mold exhaust system.

5. If the gate or runner cross-sectional area is too small or sudden change, the melt in which the flow by the shear force is too large, was turbulent dynamic flow, resulting in poor luster, in this regard, should be appropriate to increase the gate and runner cross-sectional area.

Second, the injection molding process

1. If the injection speed is too small, the surface of the molded part is not dense, showing poor luster, in this regard, can be appropriate to increase the injection speed

2. For thick-walled injection molded parts, such as cooling is not sufficient, the surface will be hairy, glossy dark, in this regard, should improve the cooling system

3. If the holding pressure is insufficient, the holding time is short, so that the density of the injection molded parts is not enough and bad luster, in this regard, should increase the holding pressure and holding time.

4. If the melt temperature is too low, making the liquidity is poor, easy to lead to poor gloss, in this regard, should be appropriate to improve the melt temperature.

5. For crystalline resin, such as PE, PP, POM and other production of injection molded parts, such as uneven cooling will lead to poor luster, in this regard, should improve the cooling system, so that the uniform cooling

6. If the injection speed is too large, and the cross-section area of the gate is too small, then the product will be dark and bad luster near the sprue, in this regard, the injection speed can be appropriately reduced and increase the cross-section area of the gate.

Third,raw material

1. Raw material particle size difference is large, making it difficult to uniform plasticization, and poor gloss, the raw material should be sieved processing

2. Raw materials in the recycled material or spout material to add too much, affecting the uniform plasticization of the melt and poor gloss, which should reduce the amount of recycled material or spout material to join.

3. Some raw materials will be decomposed and discolored during temperature adjustment, resulting in poor luster, in this regard, the temperature should be used to better raw materials.

4. The content of moisture or volatile matter in raw materials is too high, when heated, volatilized into gas, in the cavity and melt condensation, resulting in poor luster of the injection molded parts, in this regard, the raw materials should be pre-drying treatment.

5. The dispersion of some additives is too poor to make the injection molded parts gloss bad, in this regard, should be changed to a better fluidity additives.

6. Raw materials mixed with foreign materials, impurities or insoluble materials, they can not be evenly mixed with its raw materials melted together and lead to poor gloss, which should be strictly excluded beforehand these impurities.

7. If the amount of lubricant is too small, the liquidity of the melt is poor, the surface of the injection molded part is not dense, making the gloss bad, in this regard, should be appropriate to increase the amount of lubricant.

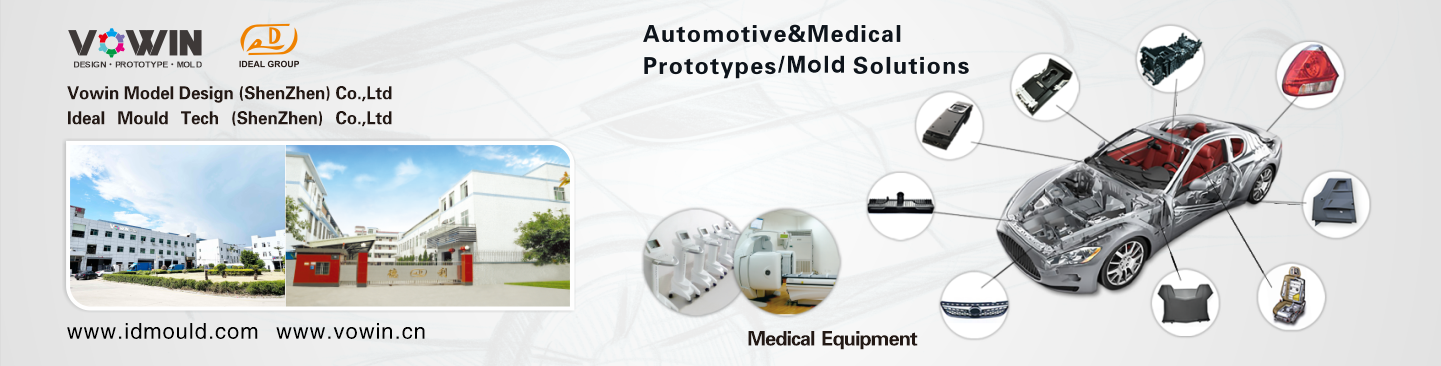

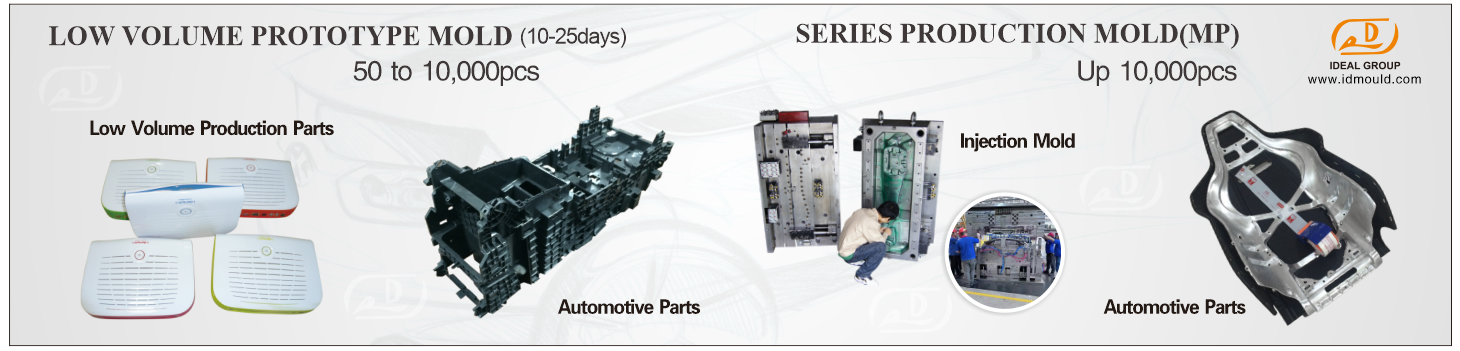

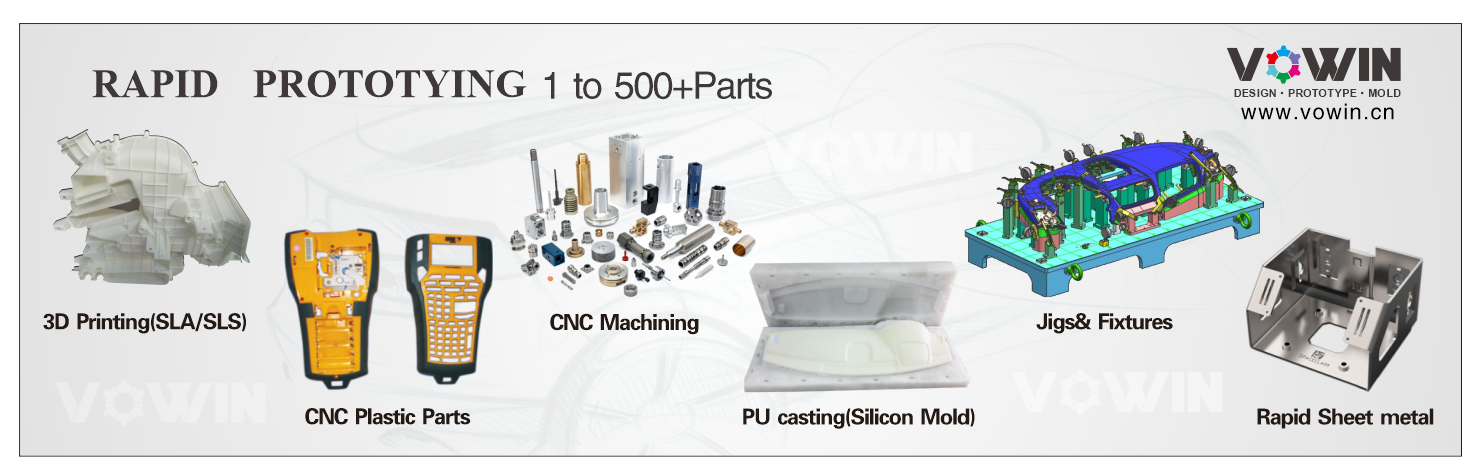

Ideal Vowin Group is an injection mould & CNC machining factory, support rapid prototyping, 3D printing, mould customization, we have recently helped our customers to complete many big projects, for more details, please visit our official website: www.idmould.com / www.vowin.cn.

If you have relevant needs,please contact us!

Ideal Vowin Group is an injection mould & CNC machining factory, support rapid prototyping, 3D printing, mould customization, we have recently helped our customers to complete many big projects, for more details, please visit our official website: www.idmould.com / www.vowin.cn.

If you have relevant needs,please contact us!

WhatsApp: +8617369230494

Wechat: 17369230494

E-mail: yuki@idmould.com/yuki@vowin.cn

Posts by Topic

Recent Posts

- What do we need to pay attention to the plastic mold machining process and machining procedures?

- What kinds of plastic mold materials?

- What is the process of mold manufacturing?

- What should be paid attention to the polishing of injection molds?

- What is easy to ignore when maintaining and overhauling injection molds?

- What are the 6 systems of plastic molds?

- What are the methods of strengthening the surface of injection molds?

- What are the methods of insulation for injection molds?

- How to solve the problem of injection mold release difficulty?

- How can we increase the brightness of ABS injection molded parts?