Resources

What are the methods of insulation for injection molds?

Release time:2024-04-11

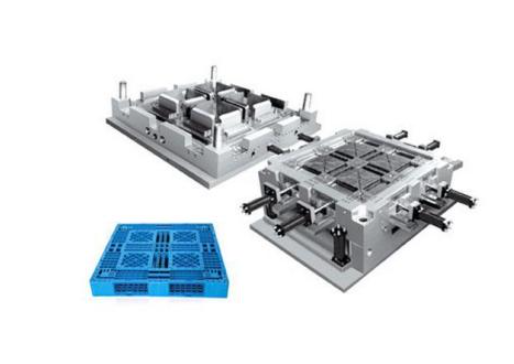

What are the methods of insulation for injection molds?

Mold temperature is a very important variable in injection molding. Regardless of the type of plastic being injection molded, it is important to ensure that the cavity mold surface is essentially wet. A hot mold surface keeps the plastic surface liquid long enough to build pressure in the cavity. If the cavity fills before the frozen skin hardens, and the cavity pressure can press the soft plastic against the metal, attachment to the cavity surface is high. On the other hand, if the plastic that enters the cavity at low pressure pauses, no matter how briefly, then its slight contact with the metal can cause staining, sometimes called gate fouling.

For each type of plastic and plastic part, there is a limit to the surface temperature of the mold beyond which one or more undesirable effects (e.g., component spillage burrs) may occur. Higher mold temperatures mean less resistance to flow.

On many injection molding machines, this naturally means faster flow through the gate and cavity, since the injection flow control valves used do not correct for this change, and faster filling causes higher effective pressures in the sprue and cavity.

This can cause overspill burrs, and since hotter models do not freeze plastic that enters the overspill area before high pressure builds up, the melt can overspill burrs around the ejector rod and spill into the parting line gap. This suggests the need for good injection rate control, and some modern flow control programmers do do this.

Generally, an increase in mold temperature reduces the formation of a condensation layer of plastic in the cavity, allowing the molten material to flow more easily through the cavity, resulting in greater part weight and better surface quality. At the same time, an increase in mold temperature will also result in an increase in the tensile strength of the part.

Insulation methods for injection molds

Many molds, especially engineering thermoplastics, operate at relatively high temperatures, such as 80 degrees Celsius or 176 degrees Fahrenheit, and if the molds are not insulated, as much heat can easily be lost to the air and to the injection molding machine as is lost to the injection cylinder.

So insulate the mold with a skeleton plate and, if possible, insulate the surface of the mold. Consider using a hot runner mold to try to reduce the heat exchange between the hot runner section and the cooled injection part. This approach will reduce energy loss and preheating time.

Ideal Vowin Group is an injection mould & CNC machining factory, support rapid prototyping, 3D printing, mould customization, we have recently helped our customers to complete many big projects, for more details, please visit our official website: www.idmould.com / www.vowin.cn.

If you have relevant needs,please contact us!

WhatsApp: +8617369230494

Wechat: 17369230494

E-mail: yuki@idmould.com/yuki@vowin.cn

Posts by Topic

Recent Posts

- What do we need to pay attention to the plastic mold machining process and machining procedures?

- What kinds of plastic mold materials?

- What is the process of mold manufacturing?

- What should be paid attention to the polishing of injection molds?

- What is easy to ignore when maintaining and overhauling injection molds?

- What are the 6 systems of plastic molds?

- What are the methods of strengthening the surface of injection molds?

- What are the methods of insulation for injection molds?

- How to solve the problem of injection mold release difficulty?

- How can we increase the brightness of ABS injection molded parts?