Resources

How to clean the mold before and after the use of plastic injection molding manufacturers?

Release time:2024-03-11

How to clean the mold before and after the use of plastic injection molding manufacturers?

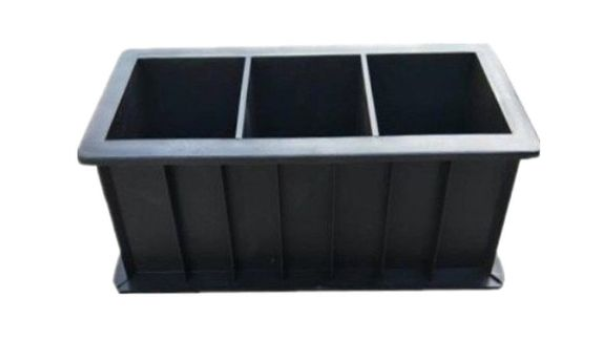

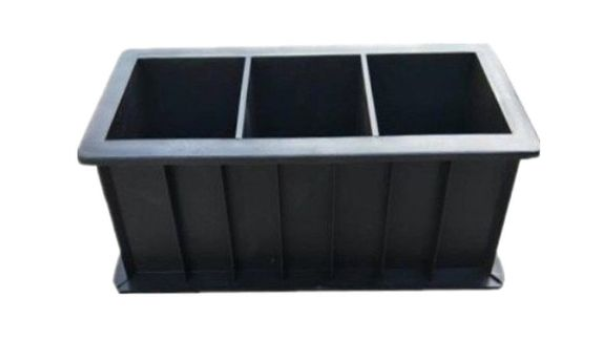

Plastic injection molding processing plant for customers to carry out injection molding product processing in order to ensure the quality of product processing needs to use high-quality molds, the mold specifications and dimensions need to meet the needs of customer products. In addition, in order to mold can be used normally also need to mold for good cleaning. Below by the Shenzhen Ideal Vowin mold manufacturers to introduce before and after the use of how to clean the mold.

1、Cleaning before use

Mold is an important tool for the production of injection molded products, raw materials to be injected into the mold to let it molding, if there are foreign objects or oil inside the mold will lead to poor product quality. Therefore, in order to ensure that the quality of injection molded products is satisfactory, injection molding processing plant in the use of molds before it is necessary to carry out a good cleaning, the first mold surface oil and rust clean, but also dredge the cooling water holes, to avoid the waterway is not blocked.

2、 the use of the process of cleaning

In the use of the mold in the process of injection molding processing plant should also be cleaned, mainly to clean the mold parting surface and exhaust grooves in the foreign matter and glue, oil, in addition, but also the parting surface and the runner surface twice a day to ensure that the mold cleanliness, to avoid the use of the process of foreign matter attached to the mold in the process of the quality of processed products are affected.

3、Cleaning after shutdown

When a batch of product processing is completed after the injection molding plant also need to clean the mold, to avoid the production of residues present in it. Therefore, after the shutdown will be timely in the mold residual water are cleaned up, to avoid the glue wire and foreign body residue in the mold, but also in the clean up after the mold inside the spray on the rust inhibitor, to avoid the preservation of the mold when the rust.

Above is the Shenzhen injection molding processing plant in different stages of cleaning the mold method, the reason why the mold to carry out the correct cleaning, is because in the process of processing injection molded products the importance of the mold is irreplaceable, so the quality of the injection molding factory will pay extra attention to the mold cleaning to avoid the mold in which there are foreign objects and dirt exist and lead to poor processing quality.

Ideal Vowin Group is an injection mould & CNC machining factory, support rapid prototyping, 3D printing, mould customization, we have recently helped our customers to complete many big projects, for more details, please visit our official website: www.idmould.com / www.vowin.cn.

If you have relevant needs,please contact us!

Ideal Vowin Group is an injection mould & CNC machining factory, support rapid prototyping, 3D printing, mould customization, we have recently helped our customers to complete many big projects, for more details, please visit our official website: www.idmould.com / www.vowin.cn.

If you have relevant needs,please contact us!

WhatsApp: +8617369230494

Wechat: 17369230494

E-mail: yuki@idmould.com/yuki@vowin.cn

Posts by Topic

Recent Posts

- What do we need to pay attention to the plastic mold machining process and machining procedures?

- What kinds of plastic mold materials?

- What is the process of mold manufacturing?

- What should be paid attention to the polishing of injection molds?

- What is easy to ignore when maintaining and overhauling injection molds?

- What are the 6 systems of plastic molds?

- What are the methods of strengthening the surface of injection molds?

- What are the methods of insulation for injection molds?

- How to solve the problem of injection mold release difficulty?

- How can we increase the brightness of ABS injection molded parts?