Resources

Six classifications of plastic molds

Release time:2023-09-08

Six classifications of plastic molds

Plastic mold is the plastic processing industry and plastic molding machine supporting, give the plastic products to the complete configuration and precise size of the tool. According to the different molding methods, can be divided into different types of molds.

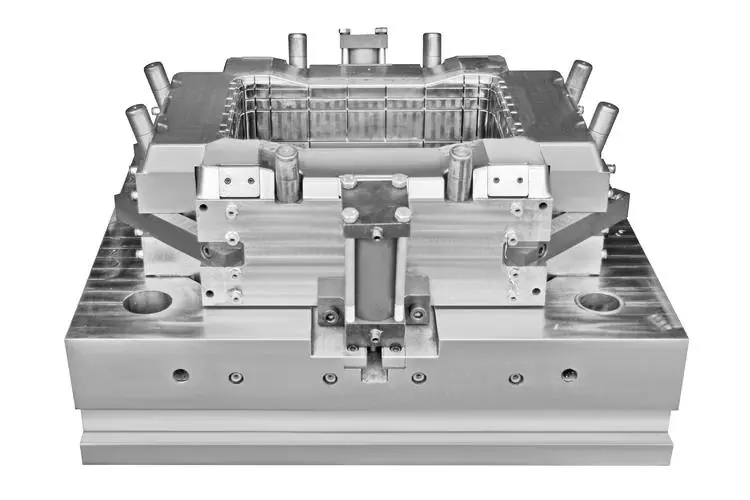

1. Plastic injection mold

It is mainly thermoplastic plastic products in the production of the most common application of a molding mold, injection mold corresponding to the processing equipment is the injection molding machine, the plastic is first in the bottom of the injection molding machine heated cylinder by the heat of the melt, and then in the injection molding machine under the impetus of the screw or plunger, the injection molding machine by the injection molding machine nozzles and the mold of the injection system into the mold cavity, the plastic cooled and hardened molding, molding to obtain the products.

Its structure usually consists of molding parts, pouring system, guiding parts, launching mechanism, temperature control system, exhaust system, support parts and other components, manufacturing using plastic mold steel. Injection molding processing method is usually only applicable to the production of thermoplastic products, with injection molding process to produce a wide range of plastic products, from daily necessities to all kinds of complex electrical appliances, automotive parts and so on are molded with injection molds, it is the production of plastic products in the production of one of the most widely used processing methods.

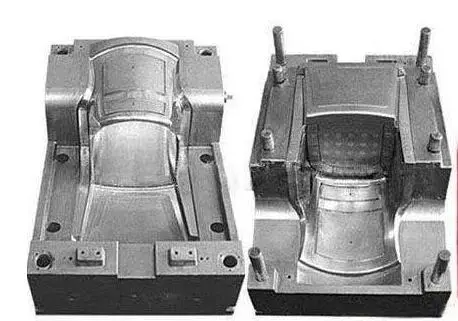

2. Blow mold

Used to mold plastic containers hollow products (such as beverage bottles, daily necessities and other packaging containers), a mold, blow molding form according to the principle of the process are mainly extrusion blow molding hollow molding, injection blow molding hollow molding, injection extension blow molding hollow molding (commonly known as injection blow), multi-layer blow molding hollow molding, sheet blow molding hollow molding and so on. Blow molding of hollow products corresponding to the equipment is usually called plastic blow molding machine, blow molding is only applicable to the production of thermoplastic varieties of products. Blow mold structure is relatively simple, the materials used are mostly made of carbon.

3. Extrusion mold

Used to mold the production of continuous shape of plastic products of a class of molds, also known as extrusion molding head, widely used in pipes, rods, monofilament, sheet, film, wire and cable coverings, profiles and other processing.

Its corresponding production equipment is a plastic extruder, the principle is that the solid plastic in the heating and extruder screw rotating under pressure conditions melt, plasticize, through a specific shape of the mouth of the die and made of cross-section and the shape of the mouth of the die the same shape of the continuous plastic products. Its manufacturing materials are mainly carbon structural steel, alloy tooling, etc. Some extrusion molds in need of wear-resistant parts will also be inlaid with diamond and other wear-resistant materials.

Extrusion process is usually only applicable to the production of thermoplastic products, its structure and injection molds and compression molds have obvious differences.

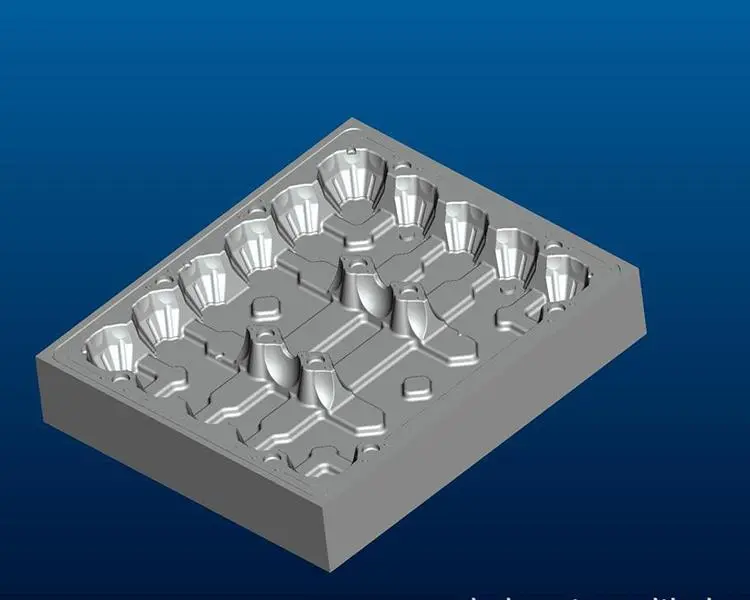

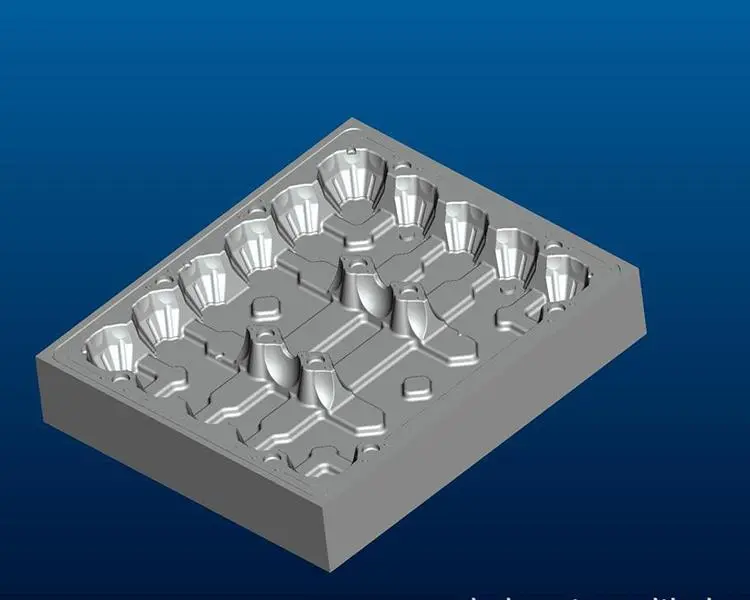

4. Suction mold

Plastic plate, sheet material as raw material molding some simple plastic products of a mold, its principle is the use of vacuum bloom method or compressed air molding method to make fixed in the concave mold or convex mold plastic plate, sheet, in the case of heating and softening of deformation and affixed to the cavity of the mold to get the required molded products, mainly used for a number of daily necessities, food, toys, packaging products production aspects.

Blister molds due to molding pressure is low, so the mold materials are mostly cast aluminum or non-metallic materials manufacturing, the structure is relatively simple.

5. Compression mold

Including compression molding and pressure injection molding two types of structural molds. They are mainly used to mold thermosetting plastics of a class of molds, the corresponding equipment is pressure molding machine.

Compression molding method according to the characteristics of the plastic, the mold will be heated to the molding temperature (generally in 103 ° 108 °), and then measured pressure plastic powder into the mold cavity and charging chamber, close the mold, the plastic in the high heat, high pressure under the action of the soft viscous flow, after a certain period of time after curing and shaping, to become the desired shape of the product.

6. High-foaming polystyrene molding die

The principle is that can be hair polystyrene in the mold into the steam molding, including simple hand-operated molds and hydraulic presses through the foam molds of two types, mainly used for the production of industrial products in the packaging products. The materials used for manufacturing such molds are cast aluminum, stainless steel, bronze, etc.

Thank you for reading! More mold information, welcome to contact us.

Posts by Topic

Recent Posts

- What do we need to pay attention to the plastic mold machining process and machining procedures?

- What kinds of plastic mold materials?

- What is the process of mold manufacturing?

- What should be paid attention to the polishing of injection molds?

- What is easy to ignore when maintaining and overhauling injection molds?

- What are the 6 systems of plastic molds?

- What are the methods of strengthening the surface of injection molds?

- What are the methods of insulation for injection molds?

- How to solve the problem of injection mold release difficulty?

- How can we increase the brightness of ABS injection molded parts?