Gasgoo.com (Shanghai May 12 nd ) Threshold of Free License Plates for Shanghai Alternative Energy Vehicles is Raised again: Owners Credits will be Examined. The application and transaction of free plates for Shanghai alternative energy vehicles will

Resources

Realize time and cost saving benefits from the use of integrated systems when compared to traditional hot runner manufacturing methods. Hot runner molds are inherently complex. They have to bring together time, temperature, flow and the pressure of p

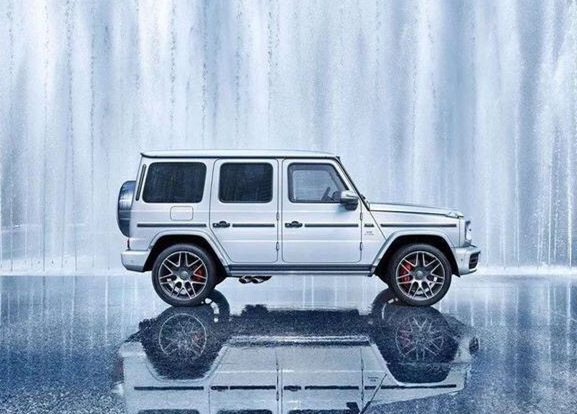

Gasgoo.com (Shanghai May 13 rd ) The sales of SUVs and alternative energy vehicles has been roaring ahead in a relatively depressing Chinese passenger vehicle market. However, the sales of SUV models has increased 52% compared against last year while

Gasgoo.com (Shanghai May 17 th ) C-class vehicles have a generally steady performance in April, with Audi A6L, BMW 5, and Benz E series still holding the leading three positions. Ford Tauruss sales shrank dramatically to 8th ranking, and Cadillac XTS

Analysts, pundits and commentators have been mesmerized of late by two very big issues facing Tesla Motors. Issue 1: Will state dealer laws allow Tesla to go on selling its cars direct, without a retail franchise network? And Issue 2: How will little

Gasgoo (Shanghai, May 26 th )- Problems including rough idling and noisy gearbox has reportedly caused bad comments from customers on Focus of Changan- Ford , a JV automaker in China, since January 1, 2015. Rough idling may cause great gasoline consu

Theres no getting around the fact that General Motors is taking a clubbing right now. A huge recall, several lawsuits, a blistering congressional hearing, apologies to consumers, potential criminal investigations -- its all bad. But then there are th

Condenser Products There are 485 Condenser Manufacturers which published 17073 Condenser Products in Condenser Category, help yourselves select the most helpful Condenser products and give you the most efficient way of sourcing auto parts from China.

This product can train the patients Lower limb 1.High-capacity CPU computer inteligent design,two-way display and control; 2.Full distance and knee angle,automatic speed adding modes; 4.With function of moment setting,safe and reliable; 5.Adopt the m

The product is used for curing and preventing the diseases like respiratory disease, angiocardiopathy, cerebrovascular disease, altitude disease, altitude reaction, infirmities of age, and etc. Advantages of V Series oxygen concentrator 1. MOREINTELLI

xpo Date: Apr 19,2016-Apr 21,2016 Venue: The Dubai International Convention Exhibition Centre Location: The Dubai International Convention Exhibition Centre, Dubai, UAE City: Dubai Country: UAE Topic: IFM 2016 Organizer: INDEX Conferences Exhibitions

Gasgoo.com (Shanghai Mar 4th) Recently, Chinese domestic carmaker BYD has announced that its net profits in 2015 jumped 552.63% to totally 2.829 billion rmb. Its observed that alternative energy vehicles are the main driver for BYDs hugely increased

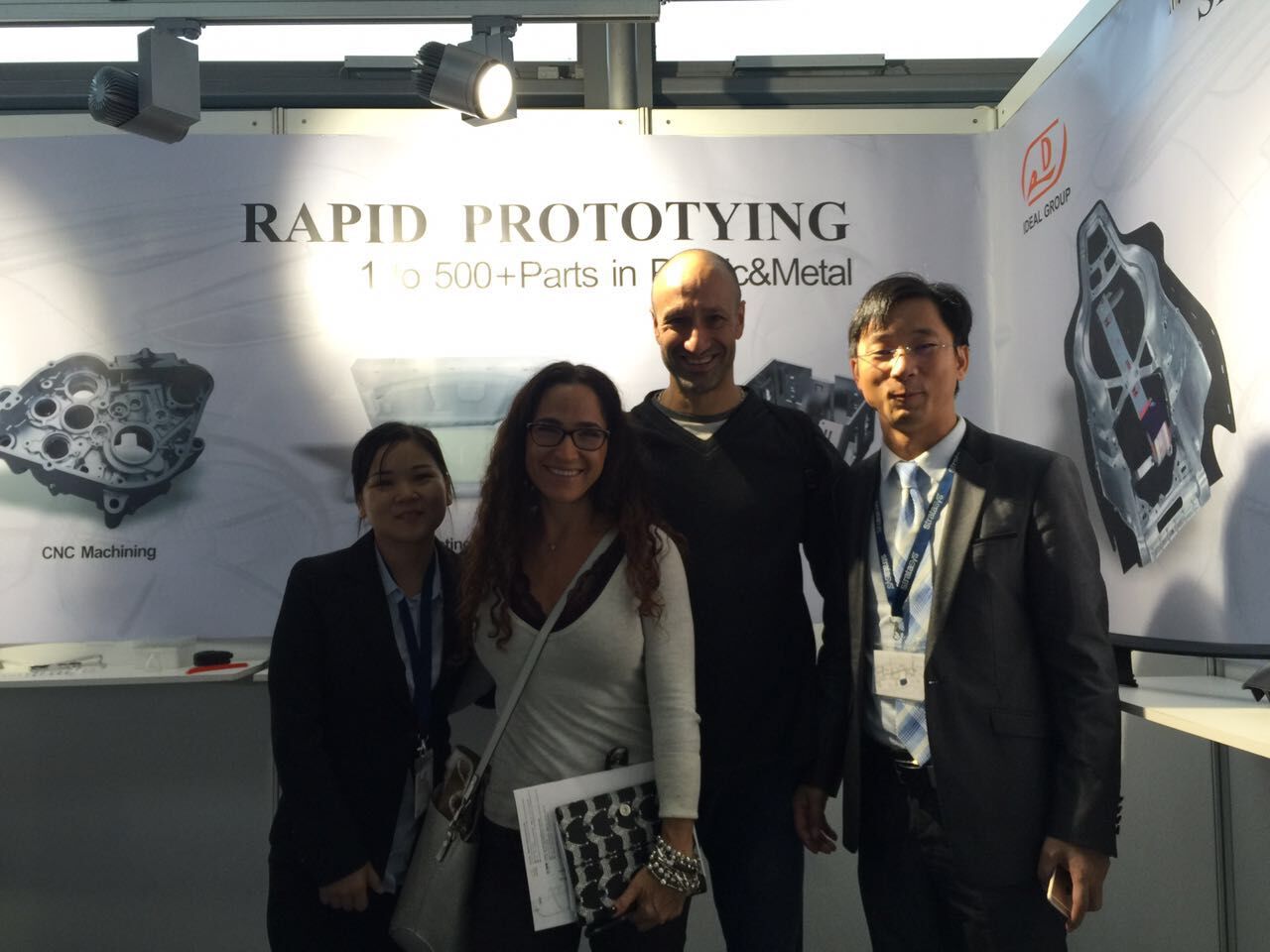

- What affects injection mold machining accuracy and productivity?

- Shenzhen top five mold manufacturers: how plastic products are processed and produced?

- Shenzhen Ideal Vowin mold manufacturer: how to effectively improve the precision of mold processing?

- Chrome plating, a process that makes cars stylish

- Six injection molding processing technologies for home appliance plastic products

- Advantages and disadvantages of injection molding vs blow molding

- What is automotive hot stamping and molding technology?

- What is the difference between a hot runner and a cold runner in the mold?

- Automotive stamping die in large, precision and other areas of progress is obvious, the rapid development of plastic and rubber molds

- The top ten problems that are likely to occur in the mold testing process