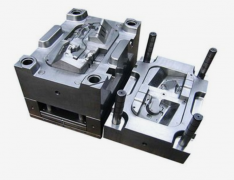

What do we need to pay attention to the plastic mold machining process and machining procedures? Plastic mold processing process is a complex and delicate process, it involves a number of links and steps, each step requires strict operation and control. B

Resources

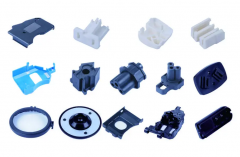

What kinds of plastic mold materials? Plastic mold materials are rich in variety, covering metal materials, non-metallic materials and plastic materials and other fields. Each of these materials has its own characteristics and is suitable for different

What is the process of mold manufacturing? Plastic mold processing process is an important part of the manufacturing industry, its process directly affects product quality, production efficiency and mold life and other aspects. The following will be int

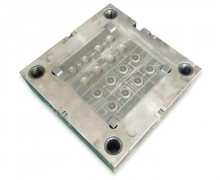

What should be paid attention to the polishing of injection molds? Injection mold polishing has two purposes: one is to increase the molds finish, so that the mold out of the products surface is smooth, beautiful, beautiful, and the other is to make the m

What is easy to ignore when maintaining and overhauling injection molds? Plastic injection mold is a production of plastic products tool, but also to give plastic products complete structure and precise size of the tool. We found that the injection mold p

What are the 6 systems of plastic molds? The functional structure of plastic mold system mainly consists of pouring system, temperature control system, molding parts system, exhaust system, guiding system, ejector system and other six systems, of which th

What are the methods of strengthening the surface of injection molds? Surface strengthening treatment methods are many, mainly carburizing, nitriding, sulfurizing, boron, nitrogen and carbon copolymerization, metal penetration, etc.. The use of different

What are the methods of insulation for injection molds? Mold temperature is a very important variable in injection molding. Regardless of the type of plastic being injection molded, it is important to ensure that the cavity mold surface is essentially wet

How to solve the problem of injection mold release difficulty? After injection molding, plastic parts from the mold cavity, whether using a single piece or multiple components of the ejector mechanism, its demolding work is generally completed once. But s

How can we increase the brightness of ABS injection molded parts? ABS injection molded parts how to increase the brightness? Ideal Vowin plastic mold manufacturer editors to make a detailed explanation of this issue: First, the injection mold 1. If the mo

What are the common problems of mold maintenance and how to solve them? Often experience customers say you have problems with the mold, and are said to be your mold quality problems, but never reflected on the use of the process there is no problem, the

What are the common problems of mold maintenance and how to solve them? Often experience customers say you have problems with the mold, and are said to be your mold quality problems, but never reflected on the use of the process there is no problem, the

- What do we need to pay attention to the plastic mold machining process and machining procedures?

- What kinds of plastic mold materials?

- What is the process of mold manufacturing?

- What should be paid attention to the polishing of injection molds?

- What is easy to ignore when maintaining and overhauling injection molds?

- What are the 6 systems of plastic molds?

- What are the methods of strengthening the surface of injection molds?

- What are the methods of insulation for injection molds?

- How to solve the problem of injection mold release difficulty?

- How can we increase the brightness of ABS injection molded parts?