How to choose the material for injection molding process? Injection molding processing commonly used injection molding materials are ABS, PC, PE, PP, PS, PA, POM, etc. Different materials have different properties, the choice of processing materials, you

Resources

What are the plastic injection molding processes? I. Injection Molding (A) injection molding Injection molding: also known as plastic injection molding, the principle is to add granular or powdery raw materials into the hopper of the injection machine, th

Do you know how to choose plastic mold materials? These tips you need to know Plastic mold working conditions and cold press mold is different, generally must be in one hundred and fifty degrees Celsius to two hundred degrees Celsius to work, in addition

What materials are used to make injection molds? 1. High corrosion resistance. Many resins and additives will erode the cavity surface layer. This type of corrosion can lead to melting and peeling of the metal in the cavity surface layer, poor surface con

How should the injection mold material be selected? The injection molding tool consists of forces and heat during operation under conditions different from those of a cold mold. The forces received are the pressure during clamping, the pressure of the mel

What are the techniques for injection molding of TPE raw materials? The use of TPE raw materials can be found everywhere in life, such as household goods, childrens toys, etc., TPE raw materials is a green environmentally friendly non-toxic materials, but

What are the material requirements for plastic molds? Plastic mold working conditions and cold punching molds are different, generally in 150 C - 200 C to work, in addition to a certain pressure, but also to withstand the effects of temperature. Now accor

What is two-color injection molding process? Two-color injection molding process is a very classic molding process, which is to use two materials to inject into one product, and can achieve different color and touch the appearance of the effect. Today I

How to set the parameter standard for injection molding process 1. Injection speed: ① Slower injection speed, the plastic in the mold cavity, there will be more heat loss, flow viscosity increases, the use of pressure loss increases; ② Higher injectio

How to choose injection mold steel? Types of injection mold steel and its selection, Jie core precision for the manufacture of injection mold steel is a lot of, their performance, processing performance and market supply price of the situation is differ

What is the performance of P20 mold steel? P20 mold steel is a type of mold welding consumables, the earliest is P20, followed by P20H, P20Ni came out one after another. So, P20 mold steel performance how? P20 mold steel performance characteristics 1. P

How to mold PCB packages using low-pressure injection molding methods The method of packaging PCBs using low-pressure injection molding process: The use of low-pressure injection molding process to encapsulate PCBs is a new process that has been gradually

- What do we need to pay attention to the plastic mold machining process and machining procedures?

- What kinds of plastic mold materials?

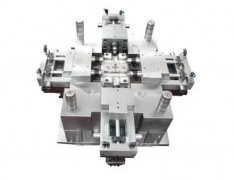

- What is the process of mold manufacturing?

- What should be paid attention to the polishing of injection molds?

- What is easy to ignore when maintaining and overhauling injection molds?

- What are the 6 systems of plastic molds?

- What are the methods of strengthening the surface of injection molds?

- What are the methods of insulation for injection molds?

- How to solve the problem of injection mold release difficulty?

- How can we increase the brightness of ABS injection molded parts?