Porsche (China) Motors Ltd. is a subsidiary of parent company Dr. Ing h.c. F. Porsche AG. Porsche China commenced operations in 2001 to support Porsche partners in China through dedicated personnel who oversee every aspect of sales marketing and after sales functions.

Resources

Porsche (China) Motors Ltd. is a subsidiary of parent company Dr. Ing h.c. F. Porsche AG. Porsche China commenced operations in 2001 to support Porsche partners in China through dedicated personnel who oversee every aspect of sales marketing and after sales functions.

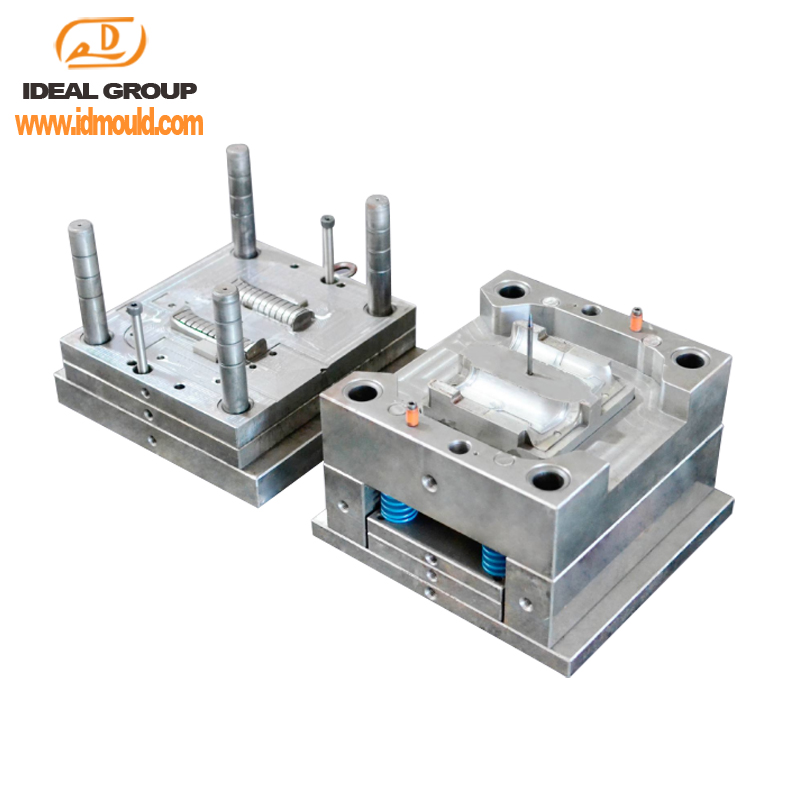

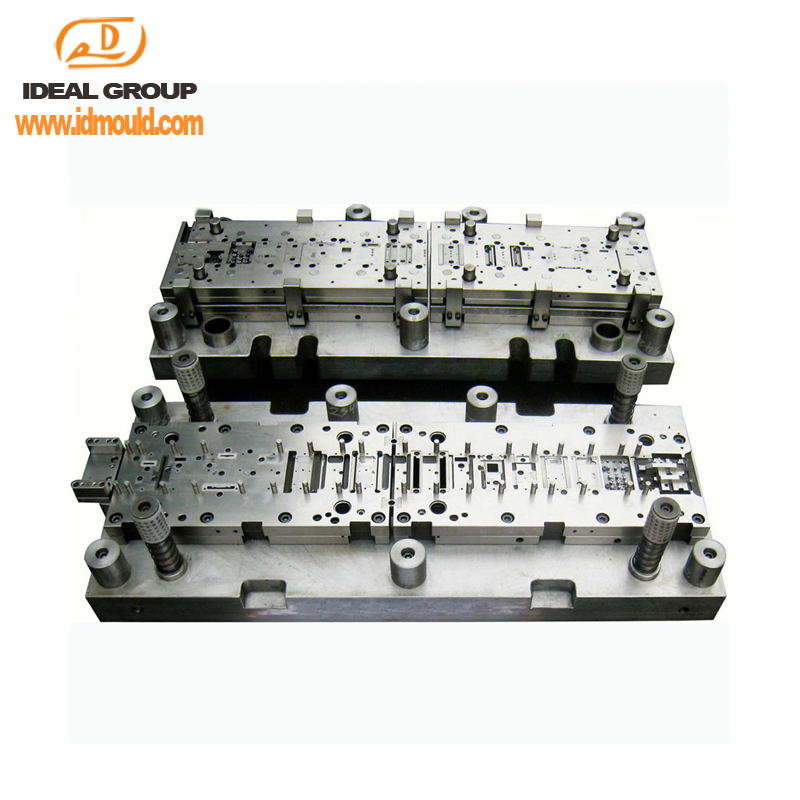

Moulds are built through two main methods: standard machining and EDM. Standard machining, in its conventional form, has historically been the method of building injection moulds. With technological developments, CNC machining became the predominant means of making more complex moulds with more accurate mould details in less time than traditional methods.

The mold cavity of a casting does not reflect the exact dimensions of the finished part due to a number of reasons. These modifications to the mold cavity are known as allowances and account for patternmaker's shrinkage, draft, machining, and distortion. In non-expendable processes, these allowances are imparted directly into the permanent mold, but in expendable mold processes they are imparted into the patterns, which later form the mold cavity.[23] Note that for non-expendable molds an allowance is required for the dimensional change of the mold due to heating to operating temperatures.

With injection moulding, granular plastic is fed by a forced ram from a hopper into a heated barrel. As the granules are slowly moved forward by a screw-type plunger, the plastic is forced into a heated chamber, where it is melted. As the plunger advances, the melted plastic is forced through a nozzle that rests against the mould, allowing it to enter the mould cavity through a gate and runner system. The mould remains cold so the plastic solidifies almost as soon as the mould is filled

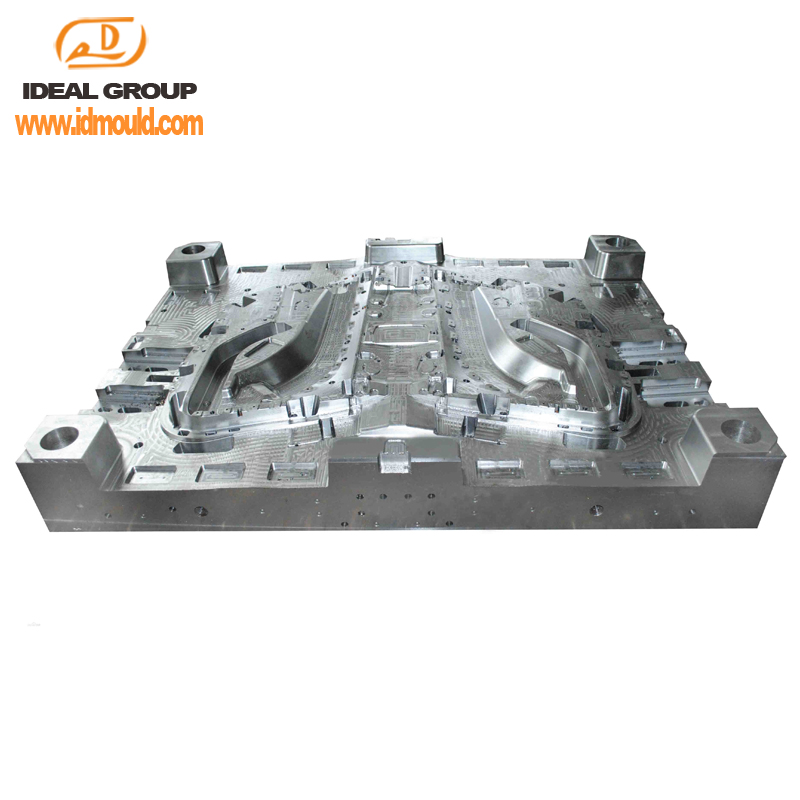

Automotive molding or car body molding are decorative and protective moldings on the car body . The term applies both to the detail and the material. Car moldings include side body molding, lower body molding, door moldings, window moldings, footrest mold

Rotational Molding (BrE moulding) involves a heated hollow mold which is filled with a charge or shot weight of material. It is then slowly rotated (usually around two perpendicular axes), causing the softened material to disperse and stick to the walls of the mold

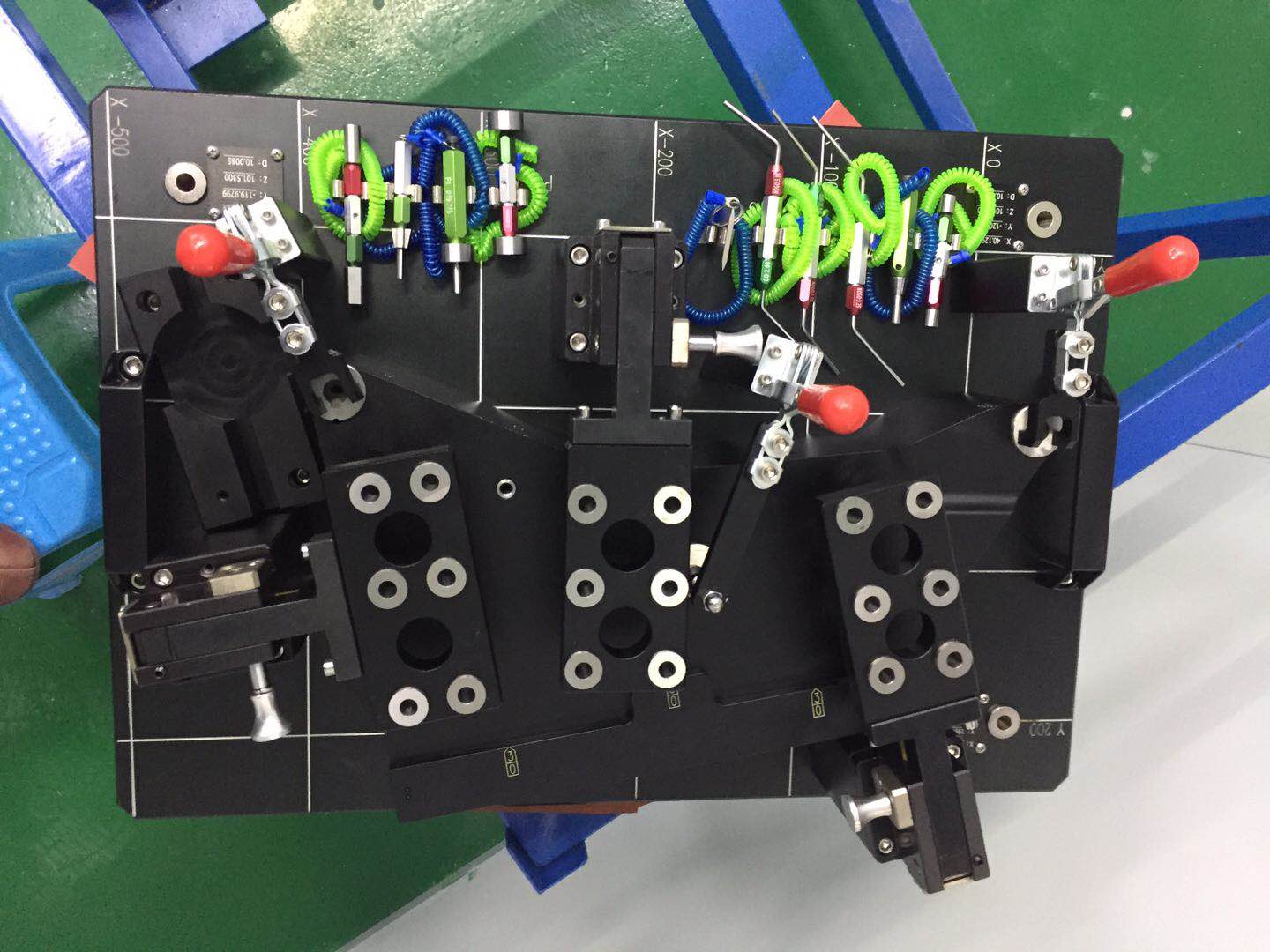

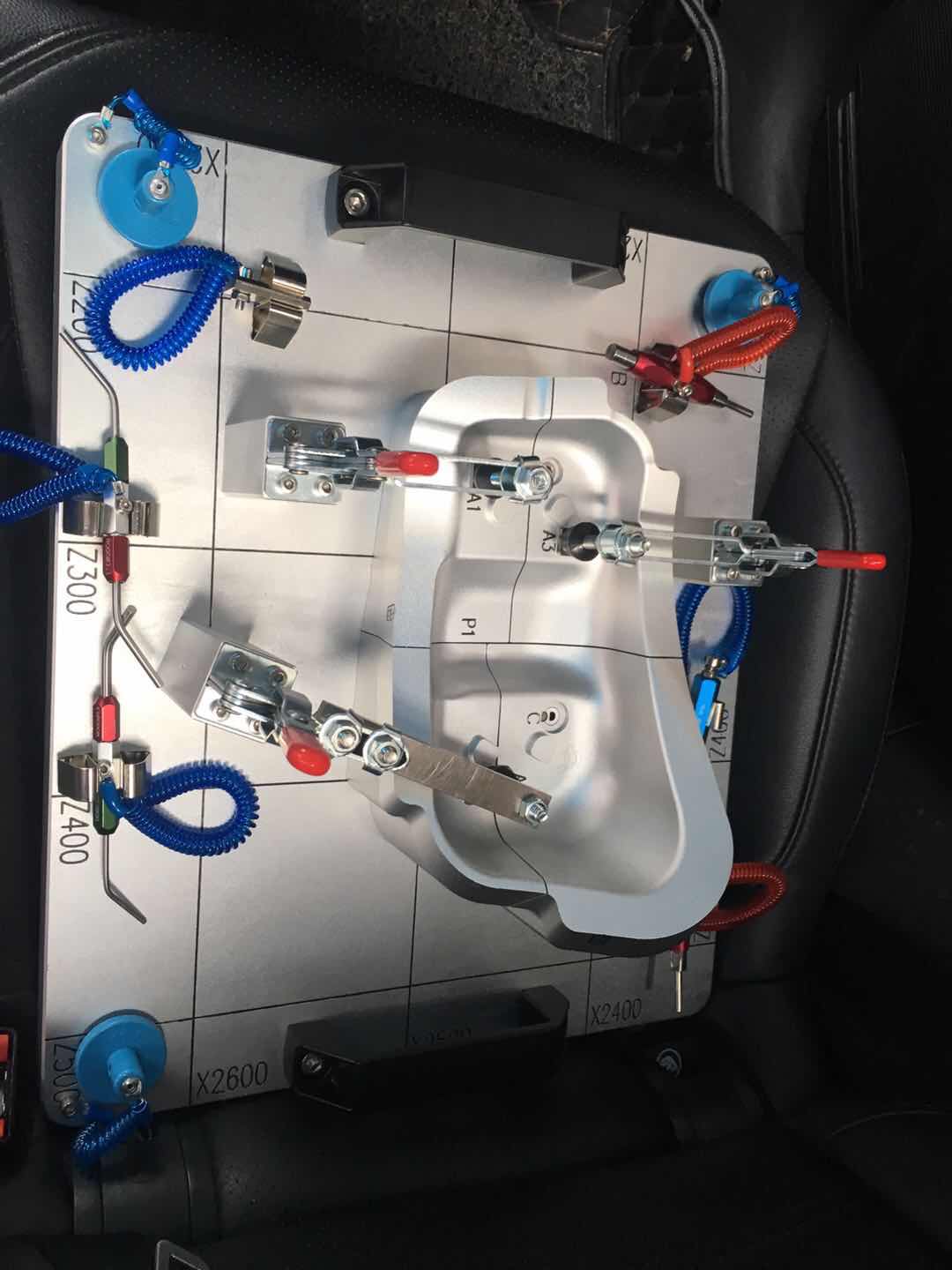

A jig's primary purpose is to provide repeatability, accuracy, and interchangeability in the manufacturing of products.[1] A jig is often confused with a fixture; a fixture holds the work in a fixed location. A device that does both functions (holding the work and guiding a tool) is called a jig.

A drill jig is a type of jig that expedites repetitive hole center location on multiple interchangeable parts by acting as a template to guide the twist drill or other boring device into the precise location of each intended hole center. In metalworking practice, typically a hardened drill bushing lines each hole on the jig plate to keep the tool from damaging the jig.

A fixture is a work-holding or support device used in the manufacturing industry.[1][2] Fixtures are used to securely locate (position in a specific location or orientation) and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability. Using a fixture improves the economy of production by allowing smooth operation and quick transition from part to part, reducing the requirement for skilled labor by simplifying how workpieces are mounted, and increasing conformity across a production run.[2]

Fixtures are usually classified according to the machine for which they were designed. The most common two are milling fixtures and drill fixtures.

Injection moulding is one of the most popular and versatile methods for mass producing plastic parts, as it has multiple advantages over other methods of plastic moulding.

- What affects injection mold machining accuracy and productivity?

- Shenzhen top five mold manufacturers: how plastic products are processed and produced?

- Shenzhen Ideal Vowin mold manufacturer: how to effectively improve the precision of mold processing?

- Chrome plating, a process that makes cars stylish

- Six injection molding processing technologies for home appliance plastic products

- Advantages and disadvantages of injection molding vs blow molding

- What is automotive hot stamping and molding technology?

- What is the difference between a hot runner and a cold runner in the mold?

- Automotive stamping die in large, precision and other areas of progress is obvious, the rapid development of plastic and rubber molds

- The top ten problems that are likely to occur in the mold testing process