bending mould, bending mold , stamping mould , stamping mold , plastic mold , plastic injection mold ,mold , injection mold, mould , moulding , plastic injection mould , injection mould

Resources

die casting , stamping mold , stamping mould , bending mould , bending mold , plastic mold , plastic injection mold ,mold , injection mold, mould , moulding , plastic injection mould , injection mould

stamping mould ,stamping mold , stamping moulding , stamping molding ,plastic mold , plastic injection mold ,mold , injection mold, mould , moulding , plastic injection mould , injection mould

die casting , die casting mold , die casting mould , stamping mould , stamping mold , bending mould , bending mold ,plastic mold , plastic injection mold ,mold , injection mold, mould , moulding , plastic injection mould , injection mould

Bending Metal Mould,bending mold, bending mould , plastic mold , plastic injection mold ,mold , injection mold, mould , moulding , plastic injection mould , injection mould

die casting ,die casting mould , die casting mold ,plastic mold , plastic injection mold ,mold , injection mold, mould , moulding , plastic injection mould , injection mould

Die Casting,plastic mold , plastic injection mold ,mold , injection mold, mould , moulding , plastic injection mould , injection mould

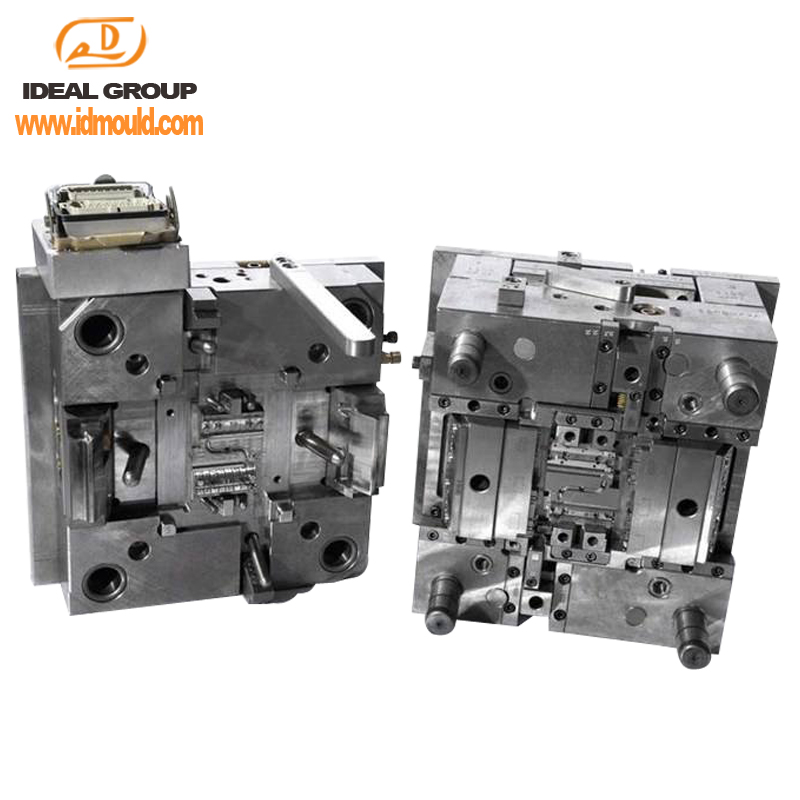

plastic mold , plastic injection mold ,mold , injection mold, mould , moulding , plastic injection mould , injection mould

plastic mold , plastic injection mold ,mold , injection mold, mould , moulding , plastic injection mould , injection mould

plastic mold , plastic injection mold ,mold , injection mold, mould , moulding , plastic injection mould , injection mould

plastic mold , plastic injection mold ,mold , injection mold, mould , moulding , plastic injection mould , injection mould

plastic mold , plastic injection mold ,mold , injection mold, mould , moulding , plastic injection mould , injection mould

- What do we need to pay attention to the plastic mold machining process and machining procedures?

- What kinds of plastic mold materials?

- What is the process of mold manufacturing?

- What should be paid attention to the polishing of injection molds?

- What is easy to ignore when maintaining and overhauling injection molds?

- What are the 6 systems of plastic molds?

- What are the methods of strengthening the surface of injection molds?

- What are the methods of insulation for injection molds?

- How to solve the problem of injection mold release difficulty?

- How can we increase the brightness of ABS injection molded parts?