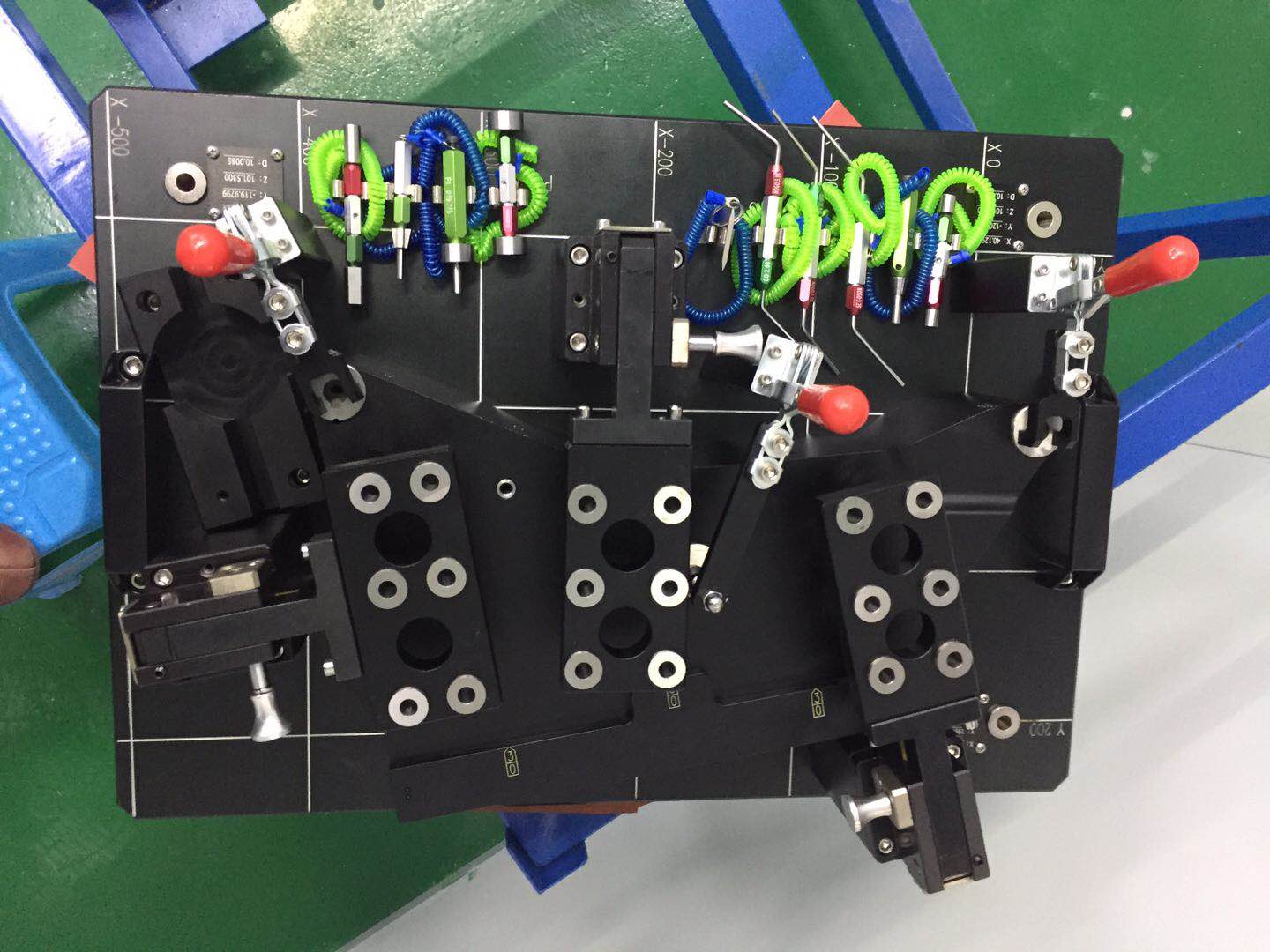

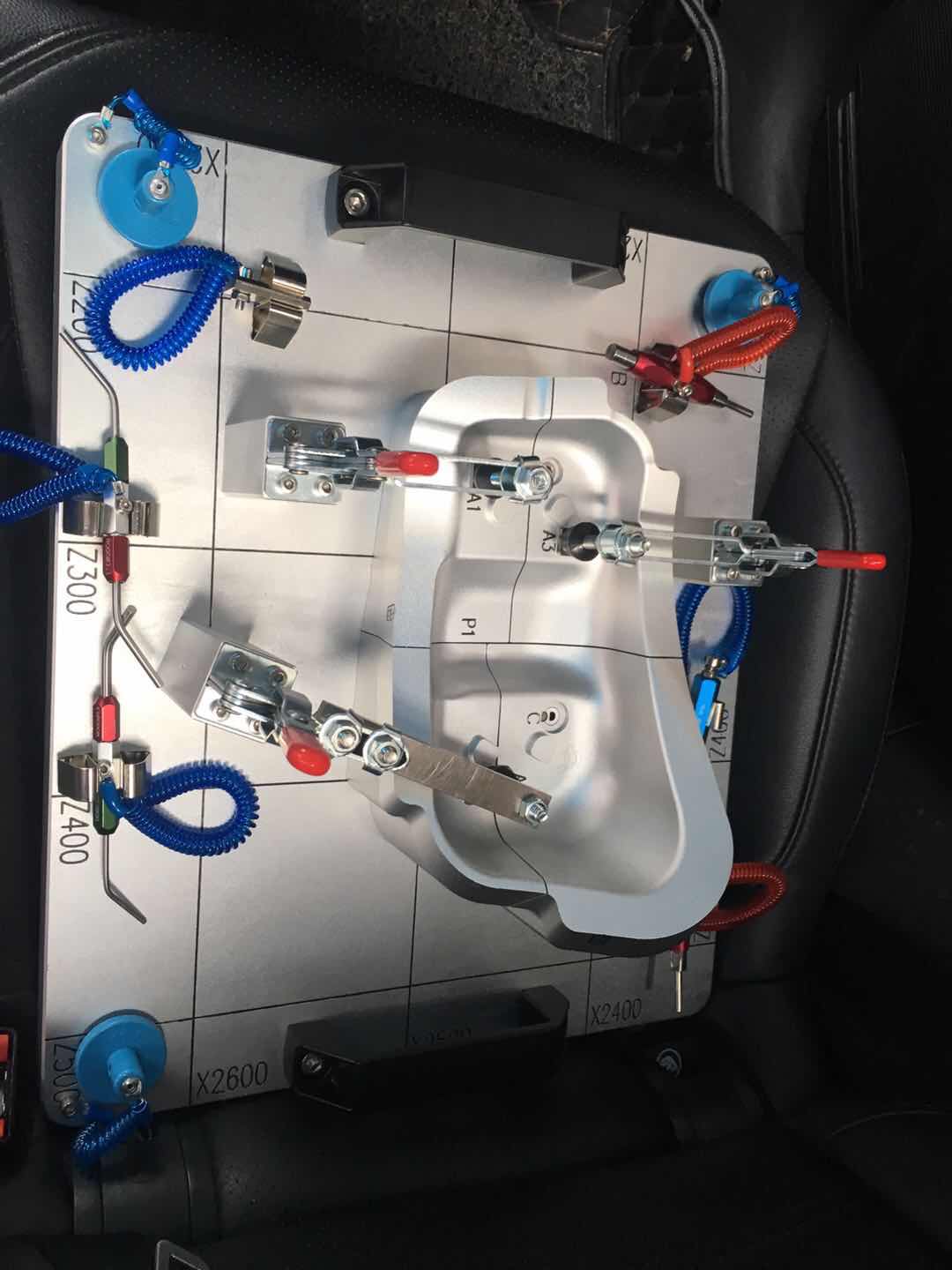

A drill jig is a type of jig that expedites repetitive hole center location on multiple interchangeable parts by acting as a template to guide the twist drill or other boring device into the precise location of each intended hole center. In metalworking practice, typically a hardened drill bushing lines each hole on the jig plate to keep the tool from damaging the jig.

Resources

A fixture is a work-holding or support device used in the manufacturing industry.[1][2] Fixtures are used to securely locate (position in a specific location or orientation) and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability. Using a fixture improves the economy of production by allowing smooth operation and quick transition from part to part, reducing the requirement for skilled labor by simplifying how workpieces are mounted, and increasing conformity across a production run.[2]

Fixtures are usually classified according to the machine for which they were designed. The most common two are milling fixtures and drill fixtures.

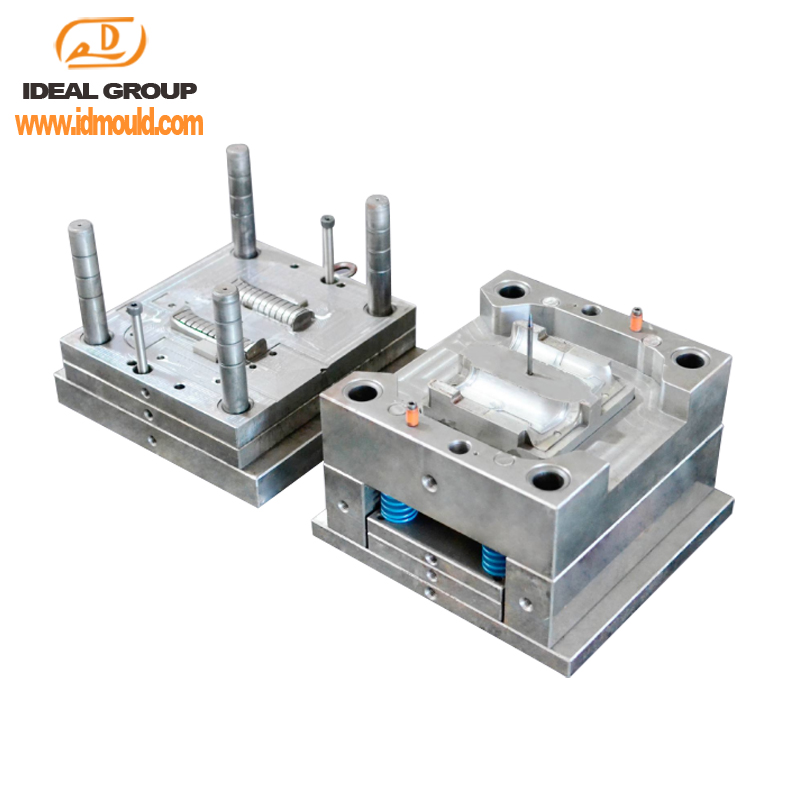

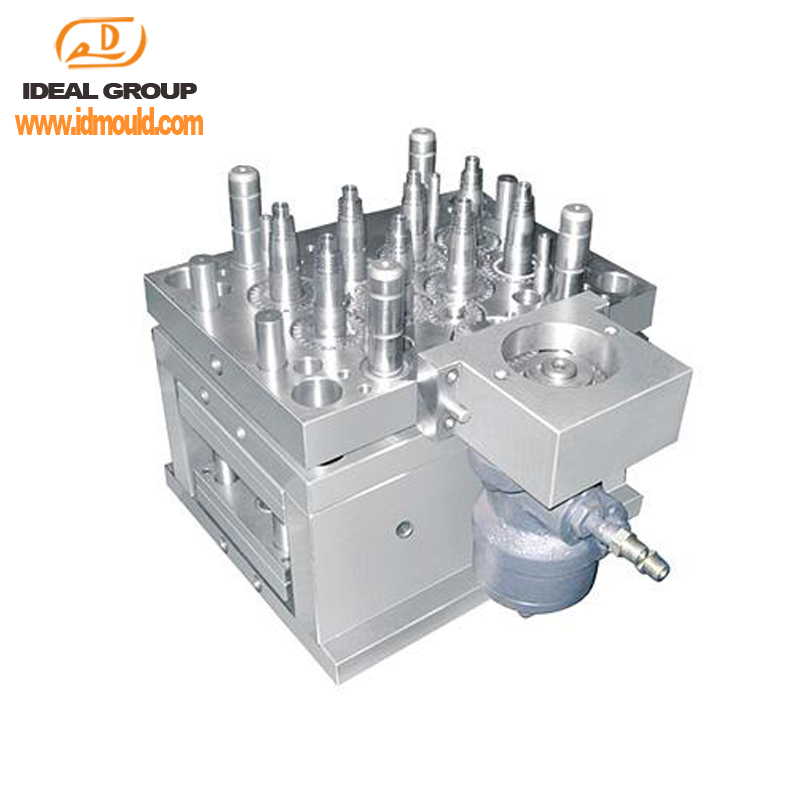

Injection moulding is one of the most popular and versatile methods for mass producing plastic parts, as it has multiple advantages over other methods of plastic moulding.

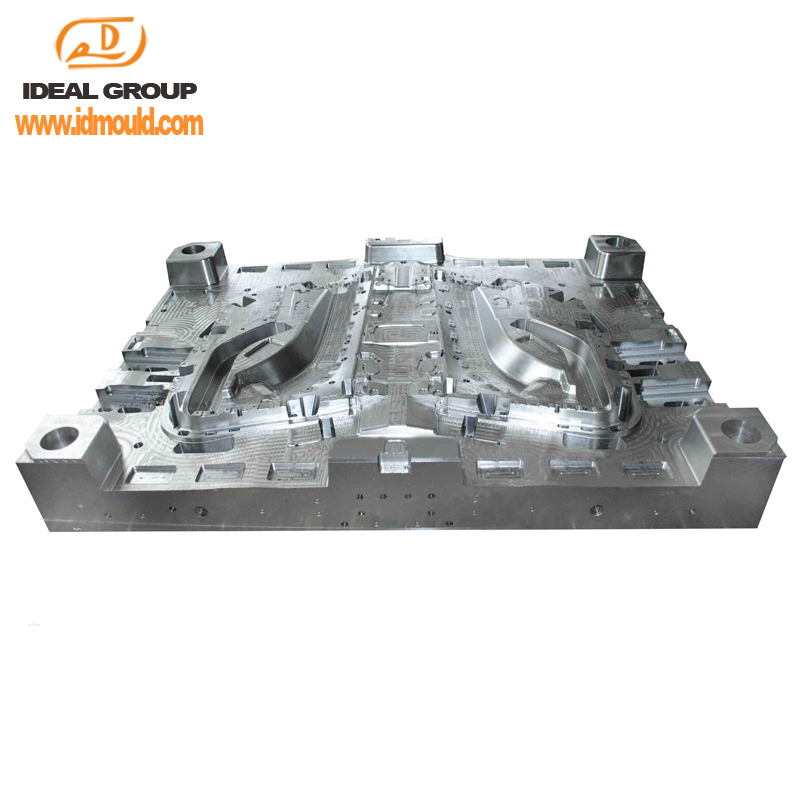

Plastic moulding is the process of shaping plastic using a rigid frame or mould. The technique allows for the creation of objects of all shapes and sizes with huge design flexibility for both simple and highly complex designs. A popular manufacturing option, plastic moulding techniques are responsible for many car parts, containers, signs and other high volume items

Injection Moulding (or Molding to use the US spelling), along with extrusion ranks as one of the prime processes for producing plastics articles. It is a fast process and is used to produce large numbers of identical items from high precision engineering components to disposable consumer goods.

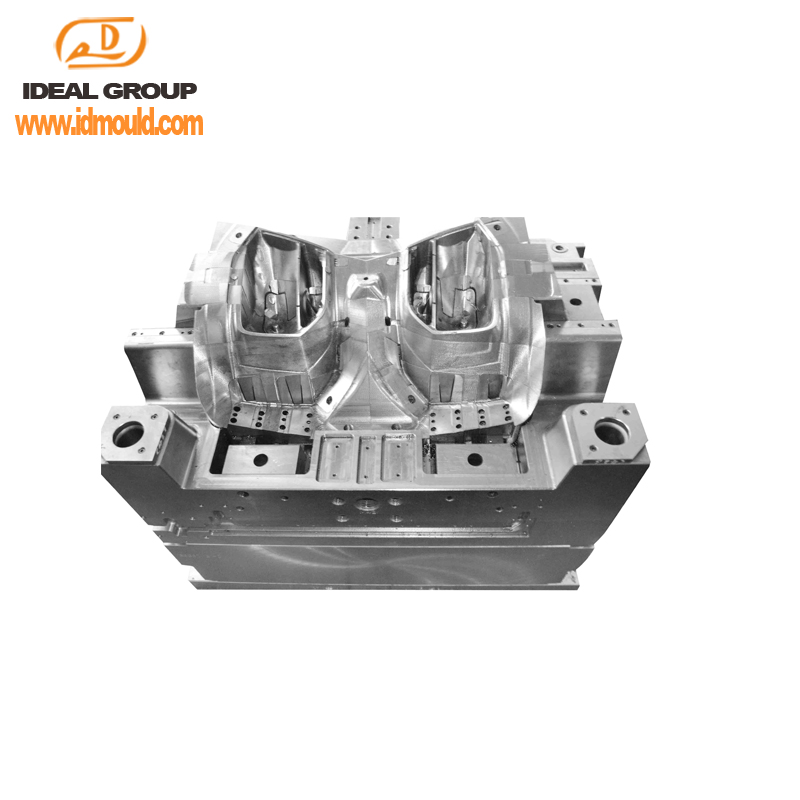

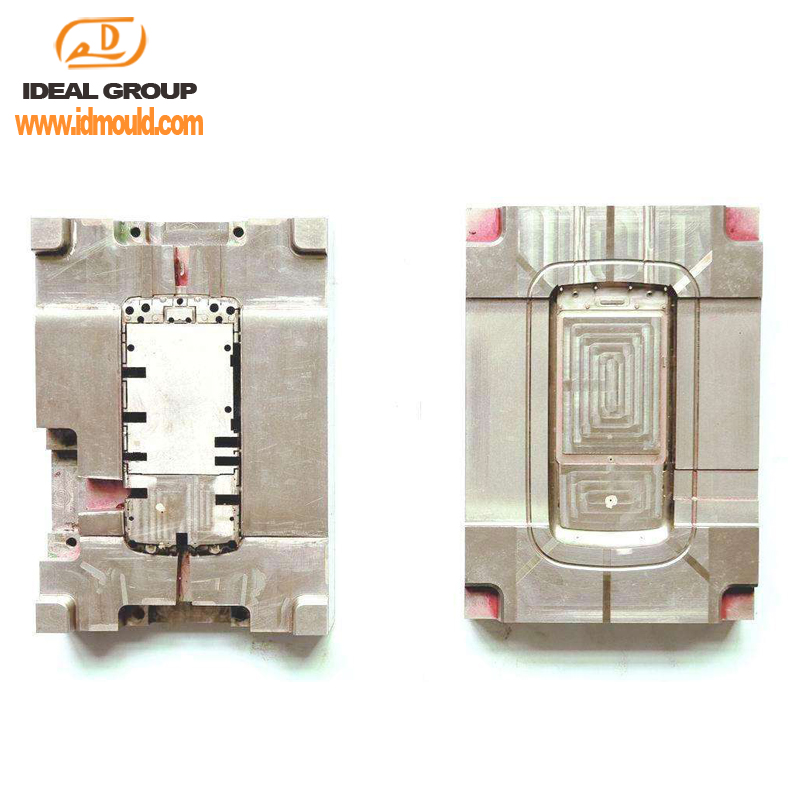

Material for the part is fed into a heated barrel, mixed, and forced into a mould cavity, where it cures and hardens to the configuration of the cavity. Moulds are typically made from metal, usually either steel or aluminium, and precision-machined to form the features of the part. They may need to split in a variety of ways to eject the finished part, or locate inserts that are bonded into the product.

Plastics are synthetically produced non-metallic compounds. It can be molded into various forms and hardened for commercial use. Plastic molding products can be seen everywhere. Examples are jars, protective caps, plastic tubes, grips, toys, bottles, cases, accessories, kitchen utensils and a lot more.

What is injection molding? Injection molding is a manufacturing process commonly used for fabricating items from plastic trinkets and toys to automotive body parts, cell phone cases, water bottles, and containers

An injection machine is made up of three primary components – the feed hopper, the screw and the heated barrel. Plastic granules for the part are fed into the heated barrel by a hopper. Plastic that is placed in the hopper is usually in powder or granular form although some resins, for instance silicone rubber, may be a liquid and might not entail heating. The material is then melted utilizing the frictional action of a reciprocating screw accompanied with heater bands. The molten plastic is then injected through the nozzle and into a mold cavity – it may seem easy, but injection molding is actually a very complex process. While in the mold cavity, the material cools and solidifies to the configuration of the cavity. When the part has hardened, the moveable platen that the mold is mounted opens and the part is ejected using ejector pins.

The cycle time of the plastic injection molding process can be broken down into the injection time, cooling time, and the resetting or changeover time. By reducing any of these times, production cost is lowered. Frequent mold changes allow inventory to be reduced and provide faster response to market requirements. The Quick Mold Change Systems from EAS lower manufacturing cost by reducing changeover time.

- What do we need to pay attention to the plastic mold machining process and machining procedures?

- What kinds of plastic mold materials?

- What is the process of mold manufacturing?

- What should be paid attention to the polishing of injection molds?

- What is easy to ignore when maintaining and overhauling injection molds?

- What are the 6 systems of plastic molds?

- What are the methods of strengthening the surface of injection molds?

- What are the methods of insulation for injection molds?

- How to solve the problem of injection mold release difficulty?

- How can we increase the brightness of ABS injection molded parts?